1. Introduction

Health and safety at work is everyone’s responsibility, but protecting the health and safety of employees, patients and members of the public who may be affected by your activities must be led by the board. The board should set the direction for effective health and safety management.

The Health and Safety at Work, etc Act 1974 states that employers must:

- assess risks to employees, customers, partners and any other people who could be affected by their activities

- arrange for the effective planning, organisation, control, monitoring and review of preventive and protective measures

- have a written health and safety policy

- ensure they have access to competent health and safety advice

- consult employees about their risks at work and current preventive and protective measures

All employees should receive health and safety training appropriate to their role and responsibilities. They must follow this when at work and using any work items. They should take reasonable care of their own and other people’s health and safety and co-operate with their employer on health and safety. They should tell someone (employer, supervisor or health and safety representative) if they think the work or precautions are putting anyone’s health and safety at serious risk.

This introduction provides all staff with an overview of the key health and safety guidance; they should be familiar with this before carrying out cleaning activities.

Section 2 gives more detailed health and safety information relating to cleaning and disinfection activities.

We encourage staff to report any concerns about the safety of any aspect of their duties to their supervisor before carrying these out.

1.1 Control of substances hazardous to health

Cleaning in a healthcare environment requires the use of chemical agents, and this is potentially dangerous. Employers are therefore required to protect employees and others who may be exposed to these agents by complying with the Control of Substances Hazardous to Health Regulations 2002 (COSHH) (as amended).

COSHH sets out 8 basic measures employers must take:

- assess the risks

- decide what precautions are necessary

- prevent or adequately control exposure

- ensure control measures are used and maintained

- monitor the exposure

- carry out appropriate health surveillance

- prepare plans and procedures to deal with accidents, incidents and emergencies

- ensure employees are properly informed, trained and supervised

An employer must prevent – or if this is not practicable – control exposure to hazardous substances and provide staff with information, instruction and training about the risks, steps and precautions the employer has taken to control these risks. Hazardous substances include:

- chemicals and products containing chemicals

- dusts

- vapours and mists

- fumes and gases

- biological and infectious agents

The EU Regulation on Classification, Labelling and Packaging 2008, which regulates the use of hazard pictograms on chemical product labelling, adopts the Global Harmonised System on the classification and labelling of chemicals. A product’s symbols and safety data sheet should be used to evaluate the hazards and risks of using chemical cleaning and disinfectant products.

1.2 Staff involvement

Staff should be involved in developing control measures to make sure they are suitable for the way they work. Encourage staff to suggest improvements, report anything they think might be going wrong and act, in response to ‘near-miss’s reports.

1.3 Training, instruction and information

Work with staff to ensure they fully understand the hazards, risk and controls: how to use controls properly and carry out practice drills and understand the language and symbols.

Health and safety guidance

1.4 Risk assessment

The employer is responsible for risk assessing all activities, tasks and procedures carried out by its employees and, if necessary, taking measures to eliminate or reduce risk.

Use a risk-based approach to determine how an area should be cleaned and disinfected, the frequency of the cleaning, the product to be used and in what concentration.

Assess the area based on the infection risk and the occupational health and safety risk. Seek a practical balance that protects both patients’ and employees’ health

Table 1 orders the steps for carrying out a health and safety risk assessment.

Table 1: Steps in a health and safety risk assessment

| Step | Action |

|---|---|

| 1 | Accurately identify potential hazards in the work area or task; a hazard is a potential source of harm or adverse health effect |

| 2 | Decide who might be harmed and how |

| 3 | Evaluate the risk and the potential for harm; risk is the likelihood that a person may be harmed or suffer adverse health effects if exposed to a hazard |

| 4 | Identify and implement controls |

| 5 | Record your findings and implement them |

| 6 | Specific controls should be incorporated in the method statement and in technical training modules |

| 7 | Frequently review the assessment and update |

Consider vulnerable workers and how the risk assessment may need to be adapted to accommodate their needs. Vulnerable workers include:

- new, expectant and breastfeeding mothers

- young and older workers

- workers with disabilities

- temporary or agency workers

- those new to the job

1.5 Health and safety controls

Risk assessments should determine what control measures are required for each task, in each situation. These should prevent or limit the exposure to hazardous substances for workers, contractors, patients and members of the public, to prevent ill-health. This can be achieved by:

- using control equipment such as total enclosure, partial enclosure, local exhaust ventilation controlling procedures (for example, ways of working, supervision and training to reduce exposure, maintenance, examination and testing of control measures)

- worker behaviour, making sure employees follow the control measures

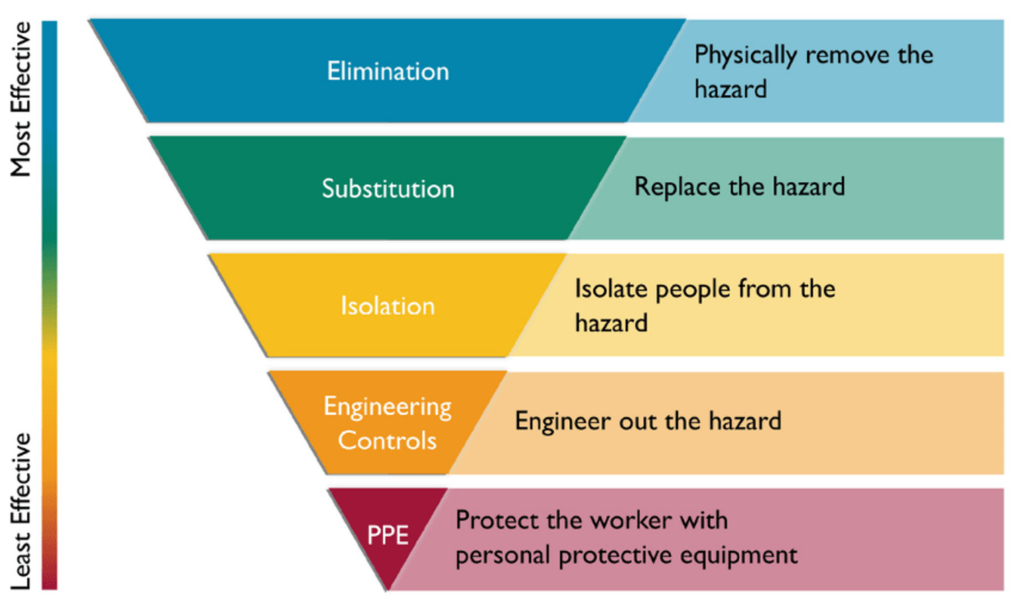

Use the ‘hierarchy of controls’ model to identify the correct controls for a given situation, as illustrated in Figure 1 below.

The control measures identified by the risk assessments should be incorporated in the method statements (see the cleaning operating procedures; if you require access to the portal and have an NHS email address, please request this by contacting: england.estatesandfacilities@nhs.net) and the technical and health and safety training modules.

Figure 1: Hierarchy of controls

Image text:

The hierarchy of controls in the NHS is a visual representation of strategies used to minimize risks in healthcare settings. It follows an inverted pyramid structure, with the most effective controls at the top and the least effective at the bottom, as follows:

- Elimination: The most effective control, where hazards are completely removed

- Substitution: Replacing a hazardous process or material with a safer alternative

- Isolation: Isolating people from the hazard

- Engineering Controls: Implementing physical modifications to reduce exposure to the hazard, such as ventilation systems or safety devices

- Personal Protective Equipment (PPE): The last line of defence, involving equipment like gloves, masks, and gowns that protect from hazards

Source: Safety Management Group

1.6 Personal protective equipment

The issue and use of personal protective equipment (PPE) are governed by the Personal Protective Equipment Regulations 2002 and the Personal Protective Equipment at Work Regulations 1992 (as amended).

PPE protects the user against health or safety risks at work. It includes items such as safety helmets, gloves, eye protection, high visibility and protective clothing, safety footwear and safety harnesses, as well as respiratory protective equipment (RPE).

PPE should be worn when all other measures are inadequate to control exposure. It protects only the wearer and only when worn correctly. If PPE is still needed after implementing other controls, employers are responsible for providing, replacing and paying for PPE. Employees must follow procedures and safe systems of work and use PPE as they have been trained to do.

Equipment must be chosen carefully; ensure that employees are trained to use it properly and know how to detect and report any faults.

Points to consider for selection and use of PPE

- Who is exposed?

- What are they exposed to?

- How long are they exposed for?

- How much are they exposed to?

- Choose products that are certification (CE) marked in accordance with the Personal Protective Equipment Regulations 2002 – suppliers can advise.

- Choose equipment that is as comfortable as possible for the user to wear – consider the size, fit and weight of the PPE.

- If more than one item of PPE needs to be worn at the same time, make sure the items are compatible, for example wearing safety glasses may disturb the seal of a respirator, causing air leaks.

- Instruct and train people in how to use PPE, for example removing gloves without contaminating Inform users why PPE is needed, when to use it and what its limitations are.

- PPE must be properly looked after and stored when not in use, for example in a dry, clean If it is reusable, it must be cleaned and kept in good condition.

Health and safety guidance

2. Health and safety key topics

This section gives further information on key health and safety areas to consider when planning and undertaking cleaning and disinfection tasks. Each key message highlights considerations and control measures, to prompt thought and discussion. They can also be accessed through icon links in the cleaning operating procedures, where a specific task is deemed to be potentially hazardous.

2.1 Safe storage and use of chemicals

Chemicals can put people’s health at risk and cause disease. If cleaning or disinfecting chemicals are used in the workplace, the law requires control of their use by assessing the risks in the workplace and implementing and maintaining effective control solutions. The safety data sheet supplied with the chemical and its hazard label should guide the risk assessment; these describe the hazards the chemical presents and give information on handling, storage and emergency measures in case of an accident.

When using chemicals, consider how a worker may become exposed and implement controls to prevent this.

Skin: some substances damage skin, while others are absorbed through it and damage other parts of the body. Skin gets contaminated by:

- direct contact with the substance, for example by touch or dipping hands in it

- splashing

- substances landing on it, for example airborne dust

- contact with contaminated surfaces – this includes contamination inside protective gloves

Also consider:

- exposure via skin puncture, for example needlestick injury

- burns from hot surfaces

- contact dermatitis

Eyes: some vapours, gases and dusts irritate eyes. Fluid splashes – for example, when dispensing, using or disposing solutions – can permanently damage eyesight.

Respiration: inhalation of substances can attack the nose, throat or lungs, while others are absorbed through lung tissue and harm other parts of the body, for example the liver. A broad spectrum of cleaning products has been reported to cause respiratory symptoms, including chlorine-liberating agents and bleaches.

Some people exposed to certain substances in the workplace can develop occupational asthma. These substances are called respiratory sensitisers or asthmagens; once the lungs become hypersensitive, further exposure to the substance, even at quite low levels, may trigger an attack. The main causes of occupational asthma are set out in section C of HSE’s asthmagen compendium.

Work-related asthma or asthma made worse by work is broader and relevant substances in the workplace will include those that irritate the airways of people with pre-existing asthma.

Ingestion: chemicals and other harmful substances can be inadvertently ingested in 4 ways:

- clearance of inhaled aerosols deposited within the ciliated airways of the lung

- ingestion of contaminated food or beverages

- transfer of contamination by hand-to-mouth or object-to-mouth contact

- the more passive but more direct mechanism of deposition of contaminants around the mouth and into the oral cavity

Health and safety guidance

2.2 Cleaning of bodily fluids

Bodily fluids are a source of infectious micro-organisms (bacteria, viruses and fungi). The main risk is infection through hand-to-mouth/nose/eye contact, but also through broken skin (cuts or scratches). Blood and bodily fluids can carry viruses such as human immunodeficiency virus, hepatitis B and hepatitis C.

‘Bodily substances’ refers to fluid or tissue issuing either directly from a patient or indirectly in the form of a specimen or otherwise. The most common types that staff with cleaning responsibilities may encounter include wound exudate, blood, sputum, urine and faeces.

Spillages may be cleaned up by nursing/departmental staff or cleaning staff; each healthcare provider’s local policy on cleanliness will have clear instructions on responsibility for this. It is vital that any staff member performing this duty has received the specific training for this type of spillage cleaning and follows the method statement fully.

Employers are legally required to plan to deal with bodily fluids. Plans need to include procedures for cleaning up and disposal of waste contaminated by bodily fluids.

Assess employees’ risk of contact with bodily fluids and implement controls to remove or minimise this risk.

- Wherever possible, contact with blood or other bodily fluids should be avoided, for example by using absorbent products to clean up

- Take all necessary precautions to prevent staff who clean or disinfect areas potentially contaminated by blood or other bodily fluids from suffering puncture wounds, cuts and abrasions; ensure approved sharps disposal containers are used and disposed of correctly.

- Protect the eyes and mouth of staff by providing visors or goggles/safety spectacles and they should wear a mask when performing tasks where splashing is

- Avoid contamination of staff clothing by providing waterproof/water resistant protective clothing, plastic aprons,

- Apply good basic hygiene practices, including hand washing before and after glove use, including to avoid hand-to-mouth/eye contact. Disposable gloves should be CE-marked for use with biological agents, and never washed and reused.

Health and safety guidance

2.3 Skin exposure

Assess the risk of skin exposure to harmful chemicals and implement controls to remove or minimise this risk.

- Consider the choice of chemical and use the least

- Consider a chemical’s physical form when selecting what to use and deciding how to use it; consider what method of application will minimise the chance of

- Reduce the chance of skin contact by modifying processes to minimise handling.

- Ensure there are good personal hygiene facilities and

- Train staff in good practice for applying and removing protective gloves and other PPE to prevent contact. Disposable PPE should be disposed of after a single use.

Needle-stick injuries

The employer duties in the Health and Safety (Sharp Instruments in Healthcare) Regulations 2013 apply to healthcare employers and contractors whose staff work on healthcare premises or under their own or the healthcare employer’s management and supervision, including cleaners.

- Employees should be trained in the safe disposal of sharps and what to do in the event of a sharps injury and follow local policies.

- An employee who has a sharps injury at work must notify their employer as soon as possible.

Hot surfaces

Contact with hot surfaces – fixtures, fittings or cleaning machinery while in or after use – and water above 43oC can cause serious injury.

- Use engineering controls to ensure water discharged from any outlet is not hotter than 43o

- Provide and maintain guarding for hot

- Use signage to warn of hot water and/or

Work-related contact dermatitis

Staff who have prolonged or frequent contact with water, particularly in combination with soaps and detergents, and/or frequent exposure to skin irritants such as cleaning products are prone to dermatitis, particularly on the hands. The skin becomes red, itchy, swollen, blistered, flaky and cracked.

- Avoid direct contact between unprotected hands and substances, products and wet work where this is sensible and practical.

- Protect the Avoiding contact will not always be possible; promptly wash any contamination from skin. Provide disposable paper towels for drying the skin. Staff should be made aware of the importance of thorough drying after washing. Wear gloves when working with substances that can cause dermatitis and moisturise hands as often as possible, and particularly at the end of work, to replenish the skin’s natural oils that help maintain the skin’s protective barrier.

- Check hands regularly for the early signs of itchy, dry or red Treatment can be more effective if dermatitis is caught early.

Personal protective equipment – gloves and aprons

PPE should be worn when adequate control of exposure to hazardous substances cannot be achieved by other control measures, and in combination with them (see Figure 1 above).

Selecting gloves

Gloves should be selected and worn based on the risk assessment for exposure to hazardous substances that could be absorbed through or damage skin.

Consider 5 factors:

- the substances handled

- all other hand hazards

- the type (for example, splash or immersion) and duration of contact

- the size and comfort for the wearer

- the task and the sensitivity, dexterity, sterility and robustness it requires

Glove manufacturers can usually provide information on how well their gloves perform against different substances. They use 3 key terms:

- breakthrough time is the time it takes a substance to permeate the glove material. This is the maximum time a glove should be used for. Choose gloves with a long breakthrough time

- permeation rate is the rate at which a substance permeates the glove The higher the rate the greater the amount of the substance that will reach the wearer’s skin. Choose gloves with a low rate

- degradation indicates the deterioration of the glove material on contact with a specific Substances can make the glove material harder, softer or cause it to swell. Choose gloves with an excellent or good resistance to degradation rating

Use manufacturers’ information, or ask their advice, to identify the best gloves for the substances being handled. Note that manufacturers’ data is for pure substances, not mixtures, and based on laboratory tests, not workplace conditions. Mixing substances may change their individual properties, and glove selection should be based on a risk assessment that covers all the substances in the mixture and their interaction.

Specific approach to latex gloves

Natural rubber latex (NRL) is found in many products used in healthcare, including medical gloves. Some people are allergic to the proteins in NRL (causing contact urticaria). Powdered gloves, to provide a barrier between the skin and NRL, present a risk of an asthmatic reaction from inhalation of the powder.

The use of NRL gloves should be avoided, unless identified as necessary by a risk assessment. If single-use latex gloves need to be used, they should be ‘low-protein’ and ‘non-powdered’.

Glove use

Disposable gloves should be checked before use for any damage such as pinholes. Care should be taken when putting gloves on and taking them off to ensure they are not damaged, and no contamination is transferred to the skin. Used gloves must be disposed of according to local policy to prevent the spread of infection.

Disposable gloves are a single-use item and should be changed:

- after each use or on completion of a task

- before the breakthrough time is exceeded; so more than 1 pair may be needed for prolonged tasks

- if they become contaminated, to prevent spread of the contamination

- if a perforation or puncture is suspected or identified

New gloves should be stored in their original boxes, away from direct sunlight, heat sources and liquids, including chemicals and in a clean area where it is unlikely they will be contaminated.

Training

Staff must be given appropriate training on:

- the hazards and risks from the substances to which they may be exposed, including the provision of information on latex allergy if appropriate

- the limitations of using gloves as a control measure

- the correct use, removal and disposal of gloves and other PPE

Skin health and skin care

Whenever protective gloves are used (regardless of material), employers must consider the need for and, if appropriate, implement suitable health surveillance for work-related dermatitis; that is, regular skin checks.

Employees must follow their organisation’s policies regarding hand hygiene and skin care. Hands should be checked regularly for signs of irritation or dermatitis and any occurrence should be reported to the occupational health department and/or local health and safety advisor.

Health and safety guidance

Disposable aprons

Disposable plastic aprons should be worn for all cleaning tasks where clothing is likely to be splashed or where the risk assessment dictates this. They may also need to be worn when cleaning rooms occupied by patients being cared for in isolation because they have specified infections: check local policies. This should be clearly indicated in the cleaning operating procedures.

For certain specialised cleaning tasks involving large amounts of fluid (for example, flood response) and likely to contaminate clothing, the wearing of overalls and waterproof footwear may be indicated by a risk assessment.

2.4 Exposure to eyes

Assess the risk of using any chemical and implement controls to remove or minimise this risk.

- Consider the choice of chemical product to select one that does not emit vapours or gases if appropriate.

- Assess the process and use equipment that minimises handling of fluids and risk of splashes.

- Protect workers’ eyes with a visor or goggles/safety spectacles when there is a risk the eyes and face could be splashed.

- Apply good, basic hygiene practices, including handwashing, before and after glove use, and avoid hand-to-eye contact.

- Plan how to deal with spillages swiftly and safely.

- Ensure adequate ventilation.

Health and safety guidance

2.5 Respiratory exposure

Assess the potential for workers to be at risk from respiratory exposure to chemicals, fumes, gases, vapours or biological agents, and implement controls to eliminate or reduce that risk. If the risk assessment indicates that there is a risk to health from respiratory exposure to harmful substances, they should be placed under a suitable health surveillance programme.

- Consider the choice of chemical product to select one that does not emit vapours or gases if appropriate.

- Ensure adequate All workplaces need an adequate supply of fresh air; this can be natural ventilation from doors, windows, etc or controlled, where air is supplied and/or removed by a powered fan.

- Consider increasing the level of ventilation when using chemicals or where there is a risk of respiratory exposure to harmful substances.

- Do not apply chemicals to hot surfaces.

- Consider how the product is applied; spray application of products may increase the potential for respiratory exposure.

Respiratory protective equipment

- RPE is not a substitute for engineering Select the correct RPE for the task; ask the RPE supplier or occupational hygiene consultant for help with this.

- Implement a management system for correctly selecting, using and maintaining RPE.

- RPE mask wearers must be fit-tested and trained in how to look after the mask.

- RPE that depends on face-fit is suitable for clean-shaven workers only.

- Make sure all required RPE can be worn with other required PPE.

- Control the provision and timely replacement of RPE.

Health and safety guidance

2.6 Exposure via ingestion

Assess the risk of using any chemical and implement controls to remove or minimise this risk.

- Consider the choice of chemical and use the safest one.

- Consider a chemical’s physical form when selecting what to use and deciding how to use it; consider what method of application will minimise the chance of contact.

- Reduce the chance of contact with the hands by modifying the process to minimise handling.

- Avoid direct contact between unprotected hands and substances, products and wet work where this is sensible and practical.

- Plan how to deal with spillages – particularly of liquids or powders – swiftly and safely to reduce the chance of inadvertent transfer and contamination.

- Ensure good personal hygiene facilities and practices: for example, washing hands before eating, smoking, etc.

- Protect the face and mouth of workers with a visor or goggles/safety spectacles and a mask when splashing is possible.

- Provide training in good practice for applying and removing protective gloves and other PPE to prevent cross-contamination. Disposable PPE should be disposed of after a single use.

Health and safety guidance

2.7 Slips and trips

Slips and trips are the single most common cause of major injury in UK workplaces.

Cleaning is a critical process in preventing slips by keeping floors free of contamination that may make them slippery. Contamination is implicated in almost all slip accidents. Timely and effective cleaning to remove contamination helps reduce accidents. However, cleaning can create slip and trip hazards: smooth floors left damp and slippery, and trailing wires from cleaning machines and waste bags left in walkways during the cleaning process. Anyone entering the area can be exposed to risk during the cleaning process, but cleaning staff are at greatest risk as they must access floors while they are being cleaned.

An effective cleaning regimen requires a good management system to help identify problem areas, decide what to do, act on decisions and check that the steps have been effective. Assess the risk of slips and trips and implement controls to prevent them.

- Ensure products are suitable for the type of contaminant and floor; use the correct amount of the right cleaning product, ensure suitable contact time with the floor and, critically, remove the solution from the floor after cleaning to remove the contaminant. Allowing a floor to air dry after wet cleaning does not remove contamination from the floor effectively and does increase the risk of slips and hygiene issues. Consider cleaning in sections and using barriers to prevent people’s access to wet floors. Barriers are far more effective than signs at defining the extent of a wet floor and keeping people from walking on it.

- Dry the floor after wet

- Consider using spill kits and/or a dedicated ‘spill team’ to ensure spillages are removed promptly.

- Dry up wet spills where possible; avoid wet mopping, which spreads the contamination and increases the risk of a slip.

- Spot clean where

- Effective training and supervision are essential to ensure cleaning is undertaken to the correct standard. Cleaners need to be informed of their duties and why the cleaning needs to be done in a particular way or at a particular Lack of understanding can lead to inappropriate shortcuts.

- Maintain cleaning equipment so it remains

- Identify and report damaged flooring, and where possible keep people away from it, for example using barriers.

- Ensure staff use the electrical sockets nearest to where they are working to reduce the risk of people tripping over trailing cables.

- Where floors cannot be kept clean and dry, slip-resistant footwear can help to reduce accidents.

Health and safety guidance

2.8 Manual handling

Musculoskeletal disorders are the most common work-related ill-health/injury reported by cleaners. They include various strain, sprain and overuse problems affecting the body’s muscles, joints and nerves. The back, neck, shoulders and upper limbs are particularly at risk. These conditions are often caused or made worse by work activities.

Cleaners are particularly at risk because cleaning is demanding and labour-intensive work; many tasks involve heavy manual work and using cleaning machines, putting strain on the heart, muscles and other tissues. Cleaners are often required to work in awkward postures for long periods, which may lead to long-term damage.

Manual handling relates to moving items by lifting, lowering, carrying, pushing or pulling. The weight of the item is an important factor, but many others risk injury: for example, the number of times an item is picked up or carried, the distance it is carried, where it is picked up from or put down (picking up from the floor, putting on a shelf above shoulder height) and any twisting, bending, stretching or other awkward postures that may be adopted while doing a task.

- Avoid hazardous manual handling operations as far as is practical by redesigning these to avoid moving the load or by automating or mechanising the process.

- Assess the risk of injury from any hazardous manual handling operations that cannot be avoided, including repetitive tasks and push–pull

- Where possible, provide mechanical assistance, for example a trolley or automated cleaning Where this is not practical, explore changes to the task, the load and the working environment.

- Ensure the right equipment to do the job is available close to where it is

- Report any problems with or damage to equipment, and any work practices causing pain or discomfort.

Health and safety guidance

2.9 Work equipment

Mechanised cleaning equipment can use electricity, water and/or steam. In wet surroundings, unsuitable electrical equipment can easily become live and make its surroundings live.

Electricity can kill or severely injure people and damage property. Ensure the safety of other staff or members of the public in the work area.

Assess the risk of using electrical equipment and implement controls to remove risk. Consider all health and safety risks from using electrical equipment, including electrical risks, using hot water and/or steam, exposure to chemicals, slip and trip hazards, noise and vibration (see other relevant health and safety sections of this guidance).

- Check that electrical equipment is suitable for the work and the way it is

- Check that electrical equipment is in good condition before starting work. Check the cable and plug are not damaged, the wires are secure, no internal wires are visible, and they have not been repaired with insulation Check that the equipment’s outer cover is not damaged in a way that can cause an electrical or mechanical hazard; burn marks or stains may suggest the equipment is overheating.

- Position any trailing wires so they are not a trip hazard and are less likely to get damaged.

- Check the equipment is suitable for the electrical supply with which it is used, and the electrical supply is safe.

- Make sure staff are trained in the safe use of the equipment and can keep others safe.

Health and safety guidance

Hand–arm vibration

Hand–arm vibration syndrome (HAVS), caused by exposure to vibration, is a painful, chronic and disabling condition that affects the nerves, blood vessels, muscles and joints of the hands and arms: tingling and numbness in the fingers, reduced grip strength and sense of touch, and vibration white finger.

The vibration risk to workers must be assessed and control measures introduced to counter this. Where a risk of HAVS remains, employers must provide employees with health surveillance, information and training on health risks and the actions being taken to control those risks.

- Make sure equipment selected or allocated for a task is suitable and can do the work efficiently. Equipment that is unsuitable, too small or not powerful enough is likely to make the task much longer to do and expose employees to vibration for Select the lowest vibration tool that is suitable for the job.

- Ask about likely vibration levels for the way the equipment will be used before deciding which new tool or machine to buy or

- Report any problems with or damage to equipment; poorly maintained equipment can vibrate more.

- Identify hazardous machines, tools and processes, especially those that cause tingling or numbness in the hands after a few minutes’ use.

- Report any early symptoms, such as tingling and numbness in the fingers, loss of feeling in fingers, loss of strength in hands, and the tips of fingers going white then red in the cold and wet and being painful on recovery.

- Plan work to avoid individuals being exposed to vibration for long continuous periods – perform work in several shorter periods with regular breaks or use rotas to share the task.

- Check whether the job can be altered to reduce the grip or pressure needed.

Health and safety guidance

Noise

Loud noise at work can damage hearing. This usually happens gradually, and it may only be when the damage caused by noise combines with hearing loss due to ageing that people realise how impaired their hearing has become.

As well as hearing loss, people may develop tinnitus (ringing, whistling, buzzing or humming in the ears), a distressing condition that can lead to disturbed sleep.

Noise at work can interfere with communication and make warnings harder to hear. It can also reduce a person’s awareness of their surroundings. These factors can lead to safety risks.

Assess the risk of exposure to noise and implement controls. If the risk assessment indicates there is still a risk to health for employees exposed to noise, they should be given suitable health surveillance (regular hearing checks).

- Consider using quieter equipment or a different, quieter

- Engineering/technical controls can reduce the noise produced by a machine or

- Consider using screens, barriers, enclosures and absorbent materials to reduce people’s exposure to noise.

- Limit the time people spend in noisy areas or using noisy

- Consider noise alongside other factors (for example, general suitability, efficiency, vibration) when hiring or buying equipment. Compare the noise data for different machines to make an informed choice.

Personal hearing protection

Hearing protection should be issued to employees where the risk assessment dictates:

- extra protection is needed above what has been achieved using noise control

- short-term protection is needed while other methods of controlling noise are being developed

Hearing protection should not be used as an alternative to controlling noise by technical and organisational means. Employees should receive training in how to use hearing protection correctly.

Health and safety guidance

2.10 Working at height

Working at height is a major cause of death and serious injury. ‘Work at height’ means work in any place where, if there were no precautions, a person could fall a distance liable to cause personal injury: for example, a fall from a ladder and through fragile surfaces.

Work must be properly planned, supervised and carried out by competent people with the skills, knowledge and experience to do the job. Use the right type of equipment for working at height.

Assess the risks and take sensible and proportionate measures to manage them; consider the height of the task, its duration and frequency, and the condition of the surface being worked on.

- Avoid work at height where it is practical to do

- Where work at height cannot be easily avoided, prevent falls using:

- a place of work that is known to be safe: for example, a non-fragile roof or concrete flat roof with permanent guardrails

- equipment such as mobile elevating work platforms (scissor lifts) and scaffolds

- PPE, such as a work restraint system that prevents a worker getting into a fall position.

- Minimise the distance and consequences of a fall by using the right type of equipment where the risk cannot be eliminated: for example, safety nets, soft landing systems or fall arrest systems.

- Do as much work as possible from the ground: for example, use extendable tools from ground level or lower items to be cleaned to floor

- Ensure workers can get safely to and from where they work at

- Ensure equipment is suitable, stable and strong enough for the job, maintained and checked regularly.

- Take precautions when working on or near fragile

- For tasks of low risk and short duration, ladders and stepladders can be a sensible and practical option:

- use the right type of ladder for the job

- workers must be competent (provide adequate training and/or supervision to help)

- use the equipment provided safely and follow a safe system of work

- workers must be fully aware of the risks and measures to help control

- Provide protection from falling

- Consider emergency evacuation and rescue

- For windows that are difficult to reach, specialist access equipment will be necessary: ropes, travelling ladders and gantries on the outside of buildings or suspended access equipment, for example cradles and building maintenance units.

Health and safety guidance

Often several organisations will be involved in these tasks. Everyone in the risk management chain must ensure activities are co-ordinated and controlled, minimising risks to their employees and others.

Publication reference: PRN00904iii